IRAN ART EXHIBITION: HOW ENGRAVING LEATHER WITH A LASER IS DONE?

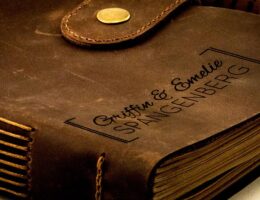

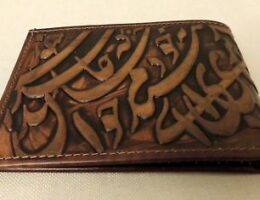

Leather is a naturally durable and flexible material created by tanning animal rawhides and skins. engraving is done on all types of leather including natural, suede, napped, nubuck, vegetan, and Alcantara. The most common applications are engraving or perforating leather include creating intricate designs for fashion garments or accessories such as purses, belts, wallets, and more.

Laser engraving is a fast, versatile way to add depth and richness to any leather item or material. It is fast, precise leather laser engraving and cutting that brings your work to life. Designers can easily engrave or cut leather products that are both high-quality and functional models. Manufacturers can quickly customize, improve prototypes and streamline their production.

Leather Laser Engraving Explained

Laser engraving leather happens when a laser beam heats the surface of the leather causing the desired area to evaporate. The laser precisely etches your wording or design into the leather surface. Engraving leather with a laser is one of the best ways to personalize or brand products or the raw material. The laser beam removes the potential of early wear and tear that tools that come into direct contact with the material.

Laser Cut Leather Explained

IRAN ART EXHIBITION: Laser Cut Leather takes place when a laser beam evaporates the leather directly in its path penetrating the entire thickness. Popular amongst fashion designers when templating. Additionally, laser cutting is the most effective way (or sometimes the only way) to perforate your leather materials with a custom pattern by making precisely sized and intricately cut patterns, compared to mechanical techniques like hand cutting or punching.

Types of leather is working with:

• Natural (Cow or Lamb hide)

• Suede

• Nubuck

• Vegetan

• Ultrasuede

Types of leather is not working with:

• Imitation leathers

• Patent leather

• Synthetic leathers with vinyl content

• Materials that don’t lay flat

Benefits of Laser Cutting

Complexity of designs – Laser cutting leather allows for the creation of incredibly complex designs that are not possible with other cutting processes.

Non-contact process – Laser cutting only affects the area that is being heated and removes the risk of abrasions or damage to the surrounding area of the material.

Environmentally friendly – Laser cutting is an environmentally friendly cutting process that vastly reduces the amount of material wastage that has been seen in the past.

Working with Leather

IRAN ART EXHIBITION: For best results engrave leather that is light or medium brown to ensure that the engraved design is visible. Avoid engraving dark leather because the engraving appears darker in color which makes the text or design less legible.

After laser cutting, your material will need some gentile cleaning to remove the residual vaporized leather.